|

Ningbo FXT Industrial Co.,Ltd.

|

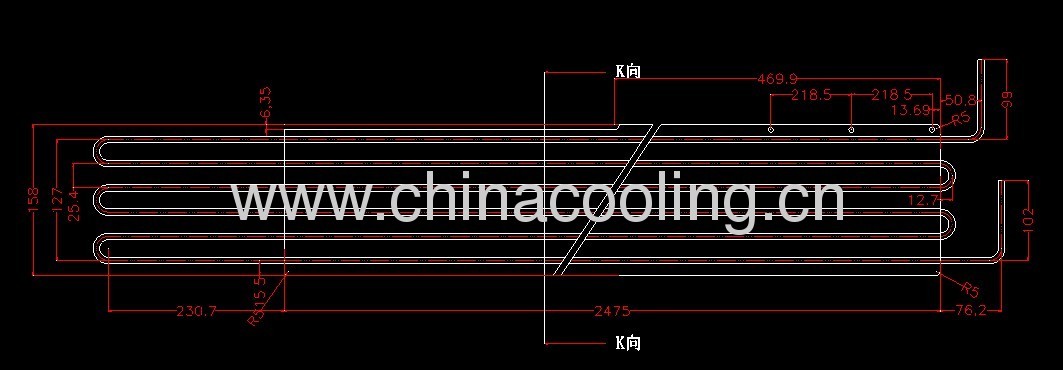

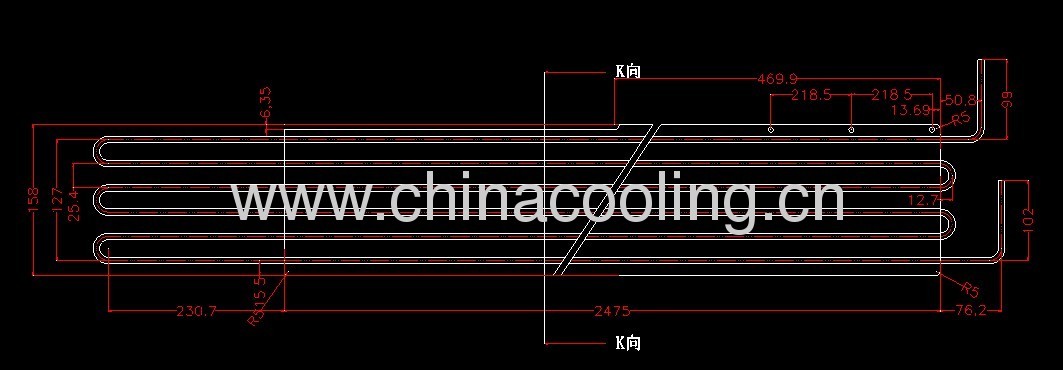

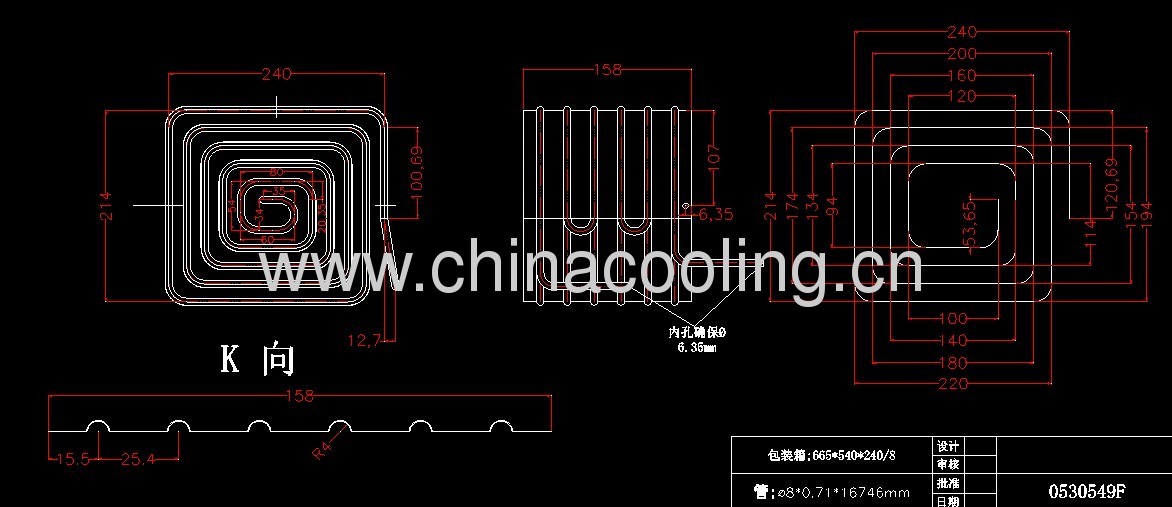

Spiral Condenser freezer plate condenser manufacurer

| Payment Terms: | T/T,L/C, |

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

spiral condensers

Specifications:

1) Raw material:

a) Rolling welded steel tube: 4.76 ~ 6.35 x 0.71

b) Bracket: steel plate SPCC thickness 0.6 ~ 2.0

c) Base mounting plate: SPCC thickness 0.6 ~ 0.8

2) Technical standards: can produce according to clients' drawing or

samples

3) Performance:

a) Surface with electrophoresis coating to prevent the corrosion

b) Inner cleanness can meet the requirement of R134a and CFC cooling system

c) Can satisfy the cooling capability requirements

Structure:

Steel tube welded with the steel plate

R134a cooling system tube inside standard:

1) Residual moisture: ≤20mg/m²

2) Residual dusty: ≤30mg/m²

3) Residual mineral oil: ≤7mg/m²

4) Residual chlorine: ≤3mg/m²

5) Sealing density: ≥1.65MPa

Specification of E-coating:

1) Coating thickness:

a) Thickness of anodic electrophoresis coating ≥12μm

b) Thickness of cathodic electrophoresis coating ≥20μm

2) Hardness of coating ≥2H

3) Impact of coating: 50cm.kg/cm impact, no crack

4) Adhesion of coating: ≥2 grade

5) Flexibility of coating: around R=3D bend 180 degrees, no crack or no fall off

6) Corrosion resistant (salt spray GB2423)

a) Anodic electrophoresis coating ≥24h

b) Cathodic electrophoresis coating ≥96h

1) Raw material:

a) Rolling welded steel tube: 4.76 ~ 6.35 x 0.71

b) Bracket: steel plate SPCC thickness 0.6 ~ 2.0

c) Base mounting plate: SPCC thickness 0.6 ~ 0.8

2) Technical standards: can produce according to clients' drawing or

samples

3) Performance:

a) Surface with electrophoresis coating to prevent the corrosion

b) Inner cleanness can meet the requirement of R134a and CFC cooling system

c) Can satisfy the cooling capability requirements

Structure:

Steel tube welded with the steel plate

R134a cooling system tube inside standard:

1) Residual moisture: ≤20mg/m²

2) Residual dusty: ≤30mg/m²

3) Residual mineral oil: ≤7mg/m²

4) Residual chlorine: ≤3mg/m²

5) Sealing density: ≥1.65MPa

Specification of E-coating:

1) Coating thickness:

a) Thickness of anodic electrophoresis coating ≥12μm

b) Thickness of cathodic electrophoresis coating ≥20μm

2) Hardness of coating ≥2H

3) Impact of coating: 50cm.kg/cm impact, no crack

4) Adhesion of coating: ≥2 grade

5) Flexibility of coating: around R=3D bend 180 degrees, no crack or no fall off

6) Corrosion resistant (salt spray GB2423)

a) Anodic electrophoresis coating ≥24h

b) Cathodic electrophoresis coating ≥96h

We send this item to Canada!

Please send us your drawing or sample for our quotation!

Related Search

Condenser

Tube Plate Condenser

Condenser Microphone

Auto Condenser

Condenser Fan

Refrigerator Condenser

More>>

.jpg)

.jpg)

.jpg)

.jpg)